‾‾‾‾‾‾‾‾‾ ONE STOP SOLUTION ‾‾‾‾‾‾‾‾‾

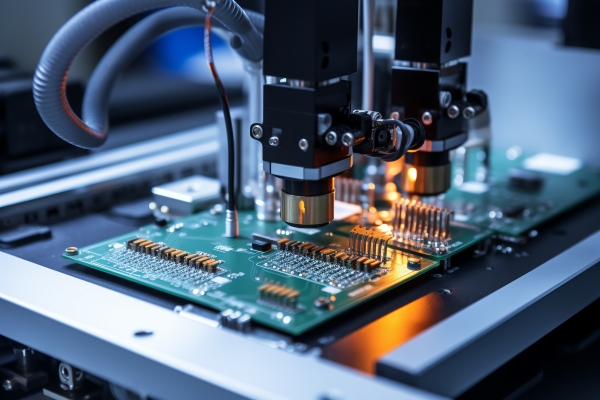

Following the production of bare circuit boards, the circuit boards are fitted with various electrical parts and components. Resistors, IC chips, capacitors, but also interfaces of all kinds are used to assemble the circuit board, depending on the requirements and layout.

Due to a large number of different components, their geometries, and their properties, the demands on vacuum technology are high.

A wide variety of technologies can be used when assembling printed circuit boards. It is possible to connect components to the circuit board with the help of Through-Hole-Technology (THT) or Surface-Mount-Technology (SMT). Depending on the application, both technologies are also combined on one circuit board in order to take advantage of both types of assembly.

Our Advantages:

![]() SMT Assembly, THT/DIP Assembly, BGA Assembly, SMT+DIP Mixed

SMT Assembly, THT/DIP Assembly, BGA Assembly, SMT+DIP Mixed

![]() Automatic Conformal Coating All-round Protection

Automatic Conformal Coating All-round Protection

![]() PCB Fabrication, Component Sourcing & Turnkey PCB Assembly

PCB Fabrication, Component Sourcing & Turnkey PCB Assembly

![]() SOIC,QFP,QFN,BGA,uBGA,CGA,LGA,CSP,Components as Small as 01005

SOIC,QFP,QFN,BGA,uBGA,CGA,LGA,CSP,Components as Small as 01005

![]() IC Programming & PCBA Testing

IC Programming & PCBA Testing

![]() 100% AOI, X-RAY, ICT & FCT

100% AOI, X-RAY, ICT & FCT

![]() No MOQ & Competitive Price

No MOQ & Competitive Price

DQS Electronic Co., Limited is a professional and reliable manufacturer specialized in PCB fabrication, components sourcing, PCB assembly services. Quick Turn PCBA prototype for quality testing. Small Batch of PCB assembly and functional testing are available as well.

Email :

Sales@dqspcba.comOur hours

24H