PCBA function test refers to the simulation of the circuit board in the actual use of conditions of operation, so as to paste the electronic components of the PCBA circuit board for electrical conductivity and based on the input and output values, to ensure that the circuit board can be in accordance with the preset programme of normal operation of a test. By testing the functionality of PCBA, manufacturing and quality problems can be avoided and unnecessary repair costs can be reduced. At the same time, it can also ensure that the products delivered to customers are intact and improve customer satisfaction. In addition, PCBA functional testing is an important means of optimising PCB design, where potential problems and defects can be identified and eliminated during the testing process. This helps to improve and optimise the circuit board design, improve the reliability and stability of the circuit board, thus greatly reducing the risk of collapse and failure.

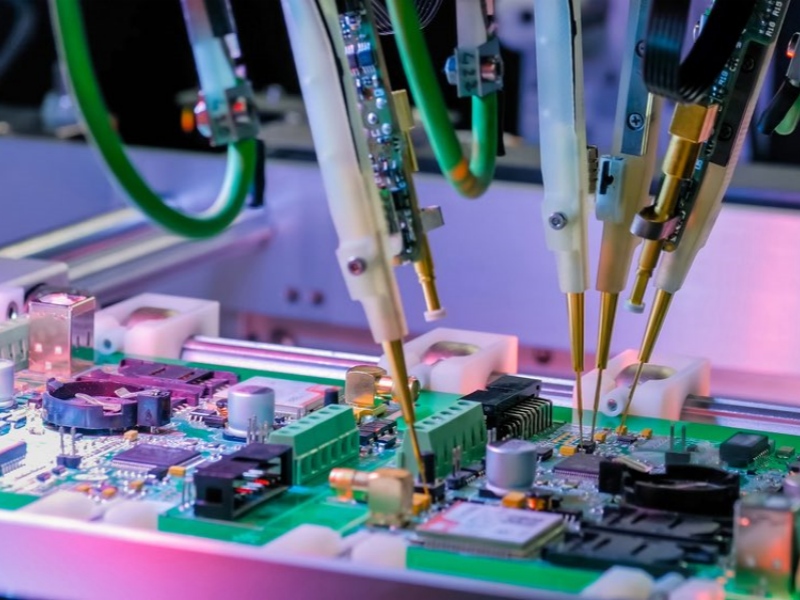

For high-volume functional testing of PCBA boards, the corresponding test fixtures are generally prescribed to assist in the efficient completion of the test content. The principle of the test fixture is to connect the test probe with the test point of the PCB board, when the power is turned on, so as to obtain the voltage, current and other key data in the circuit, and displayed on the display screen of the test fixture, to achieve the purpose of rapid detection. When customers design PCB boards, engineers need to consider the test programme and reserve PCB test points, and at the same time issue professional test documents or test programmes to us.

Automatic Conformal Coating: For electronic devices that work in harsh environments such as high humidity, high salt, dust and vibration, PCBAs are susceptible to the effects of salt spray, moisture and mould that can cause system failures, DQS can provide special automatic conformal coating process services.

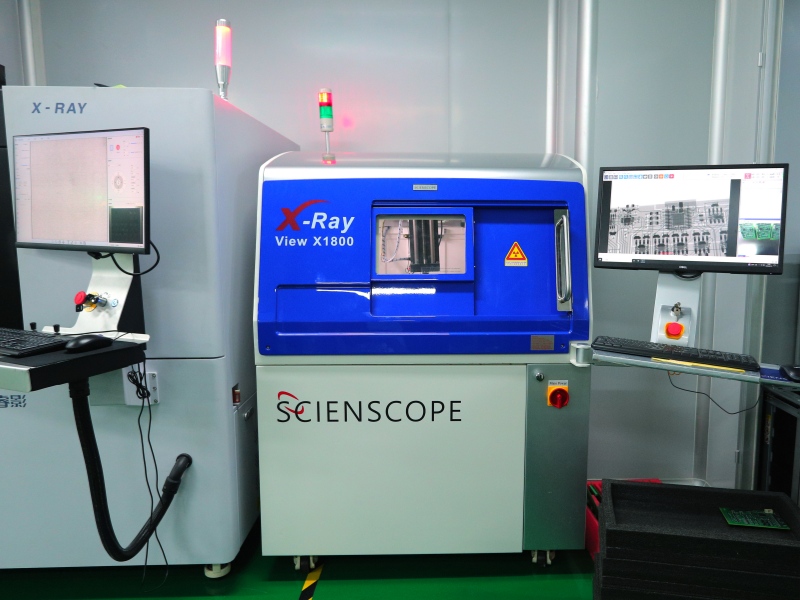

At DQS Electronic Co., Limited, we provide comprehensive PCB and assembly testing services to ensure that your electronic products meet the highest quality standards.

Email :

Sales@dqspcba.comOur hours

24H