What is Box Build Assembly?

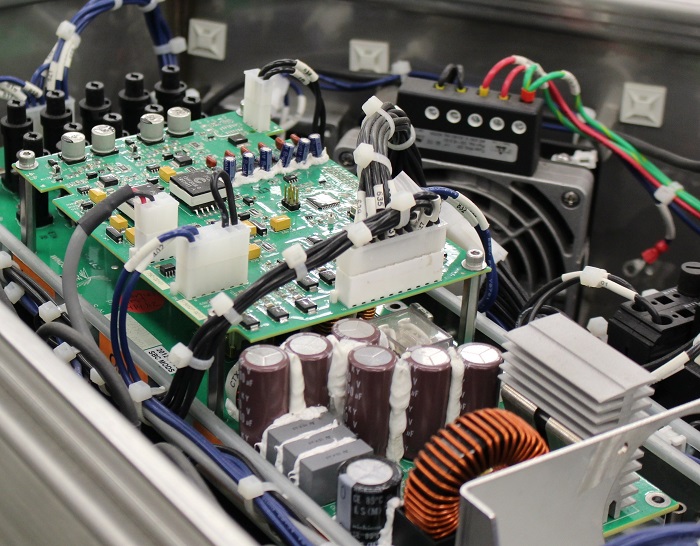

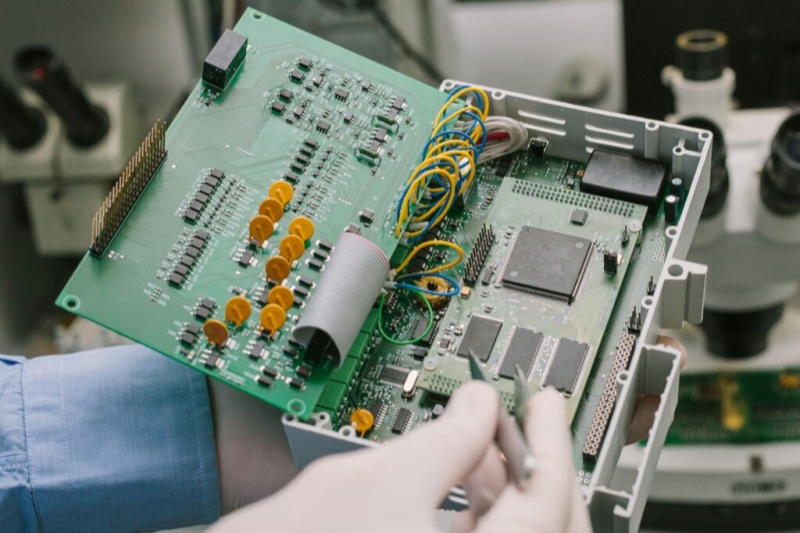

Box Build Assembly, also known as full system integration or mechanical assembly, involves the comprehensive integration of electronic, mechanical, and structural components into a complete enclosure, chassis, or case. This process transforms individual parts—such as printed circuit boards (PCBs), wiring harnesses, sensors, and mechanical modules—into a fully functional end product ready for deployment. Unlike standalone PCB assembly, box build services encompass final product assembly, testing, packaging, and logistics, ensuring seamless delivery to end users.

Types of Box Build Assembly

Box build solutions vary based on complexity and industry requirements. Common types include:

Integrates PCBs, power supplies, and control systems into enclosures. Ideal for consumer electronics, IoT devices, and industrial automation.

Combines motors, actuators, and structural components for applications like robotics, automotive systems, and medical devices.

Full integration of subsystems (e.g., telecom equipment with RF modules, shielded cables, and cooling systems) for aerospace, defense, and telecommunications.

Tailored designs with IP-rated enclosures, thermal management, and EMI shielding for harsh environments.

Our Box Build Assembly Services

DQS electronic as a leader in contract manufacturing, we deliver turnkey box build solutions backed by decades of expertise and state-of-the-art facilities. Here’s what we offer:

From design consultation to final delivery, we handle every stage:

Design Support: Collaborate with our engineering team to optimize enclosure layouts, component placement, and thermal performance.

PCB Assembly: High-precision SMT and through-hole PCB manufacturing, compliant with IPC-A-610 standards.

Mechanical Assembly: Integration of cables, connectors, and structural components with ISO 9001-certified processes.

In-Process Testing: Functional, environmental (e.g., thermal cycling, vibration), and safety testing to meet industry-specific certifications (UL, CE, RoHS).

New Product Introduction (NPI): Risk mitigation through prototype validation and DFM/DFA analysis.

Custom Packaging: Anti-static, moisture-resistant, and shock-proof solutions for global shipping.

Warehousing & Traceability: JIT inventory management and serialized tracking for supply chain transparency.

Medical & Aerospace: Cleanroom assembly, FDA/GMP compliance, and documentation for regulatory audits.

Telecom & Energy: High-voltage testing, EMI shielding, and ruggedized enclosures for 5G infrastructure and renewable energy systems.

Ready to Streamline Your Production?

Contact our team today to discuss your box build requirements. From concept to customer delivery, we ensure precision, reliability, and cost efficiency—every step of the way.

Email :

Sales@dqspcba.comOur hours

24H